NEWBio shows producers new methods that can save them sizable costs in their biomass operations, including a 20% reduction in harvesting.

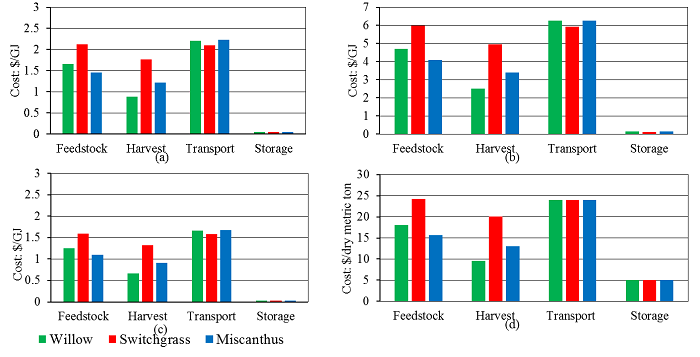

Harvesting, preprocessing, and storing biomass and then transporting it to biorefineries or other end users is a critical part of the bioenergy supply chain. Those functions can account for more than half the cost of the delivered product and have a significant impact on biomass quality (Figure 1).

The NEWBio Project’s Harvest, Preprocessing, and Logistics Team—33 research scientists, educators, and students from eight universities and agencies—was led by Jingxin Wang from West Virginia University, Timothy Volk from SUNY-ESF, and Damon Hartley from the Idaho National Laboratory. The team demonstrated a 20% reduction in the cost of harvesting biomass at sites in the region.

The team developed a data repository on biomass supply chain technologies and their associated models. Producers and processors, along with government agencies and the general public, will be able to use the information in their own operations to improve efficiency and reduce production costs in the bioenergy supply chain of the future.

NEWBio worked with various stakeholders and industry partners to perform research in eight demonstration cases across the five-year project (Table 1). Techno-economic and life cycle analyses of biomass for bioproducts were conducted in the case studies.

Contents

- Harvest Protocols and New Equipment Reduce Costs

- Improved Efficiency Through Biomass Preprocessing

- Engineering Models, and Tools to Optimize Biomass Supply Chain

- Impacts

- Harvest, Preprocess and Logistics Team Members

- Glossary Terms

- Publications by the Team

- Authors

Harvest Protocols and New Equipment Reduce Costs

One of the primary tasks of the team was to reduce the harvesting cost per ton of biomass feedstocks from willow and perennial grasses, such as miscanthus and switchgrass. Many biomass feedstocks can be harvested with traditional agricultural or forest harvesting equipment; however, short-rotation woody crops such as willow require different equipment and special processes for efficient harvesting.

Accomplishments

- Worked with New Holland to develop and monitor the performance of a forage harvester that, as part of a single-pass-cut-and-chip harvesting system, producers can use to efficiently harvest biomass crops.

- By characterizing hundreds of samples from large scale harvesting operations the team generated data on the variability of the quality of willow biomass (e.g ash, moisture and energy content), which is essential to understand when developing conversion systems

- Designed a data-collection system and integrated it with the harvester’s onboard GPS and computer system. Studies of large-scale willow harvesting showed that the capacity of the New Holland machine has improved as efficiency increased and down time decreased.

- Designed and disseminated willow and switchgrass harvesting protocols that producers are now using to improve their operations.

- The researchers’ work showed how producers can reduce their cost of harvesting biomass by as much as 20% by using the new equipment and following protocols that best fit into their operations.

Improved Efficiency Through Biomass Preprocessing

Preprocessing of biomass through drying, size reduction, storage, and compaction increases transportation efficiency, reduces delivered costs, maintains or improves biomass quality, and improves conversion efficiency when feedstocks are converted to biofuels or other bioproducts.

The team analyzed different pretreatment methods and incorporated them into life cycle analysis of different systems. Pretreatments like hot water extraction (HWE), where willow or other wood chips are cooked in water, are effective at reducing ash content and increasing energy content while producing sugar streams and other compounds that can be sold. Pellets made from HWE wood did not reabsorb moisture, which makes storage much easier and less costly. They also researched torrefaction, a process that roasts biomass at high temperatures, resulting in a charcoal-like substance, to increase biomass energy content and improve its handling characteristics. A high-throughput technique was developed to evaluate pyrolysis of biofuel conversion for a range of biomass feedstocks.

Storage is a critical part of handling biomass feedstocks, because large amounts of dry matter can be lost during the time the feedstocks are stored. It investigated the requirements for storing biomass such as willow and perennial grasses, and assessed how long-term storage affects its quality. This information was used to develop guidelines for storage of different sources of biomass.

Accomplishments

- Tested pilot systems with commercial partners to find out how preprocessing feedstocks for densification and storage affects transportation and conversion of the feedstock into fuel at a later date.

- Demonstrated that preprocessing biomass through drying, size reduction, storage, and compaction can increase transportation efficiency, reduce delivered costs, and improve efficiency when feedstocks are converted to biofuels or other products.

- Conducted studies on storage piles with willow biomass from harvests at different times of the year to develop information on how these piles and the quality of the willow biomass change over time. This information provides insights into how to manage storage piles to maintain quantity and quality over time.

- Along with commercial partners, incorporated real-life data into large-scale harvesting and storage studies across the Northeast.

- Biorefineries and other processors are using this information to choose the best preprocessing methods for their purposes, more efficiently and cost-effectively converting biomass into biofuels and other bioproducts.

Engineering, Models, and Tools to Optimize Biomass Supply Chain

The team performed techno-economic analysis, cost engineering, and life cycle analyses on the handling of biomass—all the way from biomass feedstock development, harvest, transportation to densification through preprocessing and storage. The analyses were used to estimate costs for supply chain and its components such as preprocessing and storage under different scenarios.

For example, Figure 4 shows the harvest and logistics cost of upstream processes. The costs for willow to produce biofuel, biopower, and pellets are $4/GJ, $13.5/GJ and $2.7/GJ. Costs for switchgrass are $5.6/GJ, $16.9GJ and $3.8/GJ. Costs for miscanthus are $4.6/GJ, $13.9/GJ and $3.1/GJ. (GJ, gigajoule, is a metric unit for energy content. 1 GJ equals approximately 947,817 Btu.)

The total logistics cost for willow, switchgrass, and miscanthus are $52/dry ton, $68/dry ton, and $53/dry ton, respectively.

The team also used their analyses to identify 20 locations meeting the specified criteria for a biorefinery in the Northeast; of those, seven were selected as having better social acceptance and economic viability (Figure 5). A regional biorefinery would provide producers with a convenient market for biomass feedstocks.

Accomplishments

Developed and optimized supply chain models, incorporating biomass harvest production and cost data analysis from leading companies and real case studies in the region.

- Optimized models for energy producers and processors to determine the most efficient combination of harvest, transport, and preprocess methods, based on the feedstock and energy product being produced. These models are helping companies develop more efficient and profitable commercial enterprises.

- Integrated these models with spatial transportation and infrastructure data to identify 20 promising locations for biorefineries across the Northeast, then narrowed that down to seven that had the highest social acceptance and economic viability indicators. This analysis provides companies and communities with vital information for future siting decisions.

Impacts

For perennial crop systems such as willow, miscanthus, and switchgrass, harvesting and transportation can account for 40 to 60% of the delivered cost of biomass. The Harvest Preprocess and Logistics Team has developed and demonstrated new commercial systems to reduce the cost of harvesting biomass by 20%, and the overall cost of handling biomass before it’s delivered to a biorefinery can be decreased significantly.

A public data repository now exists which provides objective, comprehensive supply chain technologies and business models for bioenergy producers and processors. Detailed research findings are available in the publications listed below.

The team designed, developed, and demonstrated efficient methods of harvest, preprocess, storage, and transportation that will effectively deliver biomass feedstocks that are high quality, in large quantities, and commercially affordable. Such improvements are crucial in developing economically feasible methods for commercial utilization of biomass energy feedstocks. If producers can grow, store, and deliver biomass to their customers more efficiently and at lower costs, both producers and customers are more likely to be profitable, contributing to a stronger, more viable renewable energy industry in the Northeast.

The Harvest, Preprocess and Logistics Team

Team Leaders: Jingxin Wang, Professor of Wood Science and Technology, West Virginia University; Timothy Volk, Senior Research Associate, SUNY-ESF; Damon Hartley, Bioenergy Technologist, Idaho National Laboratory.

Team Members:

- Graduate Students: John Vance, Amy Falcon, Weiguo Liu, Yuxi Wang – West Virginia University

- Tristan Brown, Mark Eisenbies, Karl Hallen, and Graduate Students: Daniel de Souza and Obste Theramse – SUNY ESF

- Tom Richard, Dan Ciolkosz, Jude Liu, Kay DiMarco; and Graduate Students: Ryan Baxter, Anahita Bharadwaj, Veronika Vazhnik, and Charlynn White – Penn State

- Sabrina Spatari and Kim Marcellus – Drexel University

- Kwesi Boateng and Michelle J. Serapiglia – USDA-ARS ERRC

Glossary Terms

- Densification – compacting biomass to increase its energy density and make it easier to handle

- Hot-water extraction – cooking chips in water to extract the hemicellulose material while leaving the cellulose and lignin intact. This results in a material with less mass, a higher energy content, and lower ash content.

- Pyrolysis – a thermochemical decomposition method to break down large molecules into smaller molecules, performed by preprocessing biomass at high temperatures in the absence of oxygen into more useable fuel. Products can include biochar, bio-oil, and gases such as methane.

- Torrefaction – an oxygen-absent thermal preprocess treatment of biomass at 200-300 degree C temperatures, which causes physical and chemical changes resulting in thermal decomposition of the hemicellulose and leaving a charcoal-like substance. Learn more in this case study of Terra Green Energy.

Publications by the NEWBio Harvest, Preprocessing, and Logistics Team

For more information, see the Resources from the NEWBio Project: The Northeast Woody/Warm-season Biomass Consortium

Journal Publications, Fact Sheets, Research Summaries, Case Studies, Webinars, Video, Curriculum

Journal Publications

- Switchgrass yield and quality on reclaimed surface mines in West Virginia: II. Feedstock Quality and Theoretical Ethanol Production. Brown, C., T. Griggs, and J. Skousen. 2015. Bioenergy Research. DOI 10.1007/s12155-015-9657-3

- Switchgrass biofuel production on reclaimed surface mines: I. Soil quality and dry matter yield. Brown, C., T. Griggs, T. Keene, M. Marra, and J. Skousen. 2015. Bioenergy Research. DOI 10.1007/s12155-015-9658-2

- Planting rates and delays during the establishment of willow biomass crops. Bush, C., T.A. Volk, M.H. Eisenbies. 2015. Biomass and Bioenergy. Vol. 83, December 2015. Pp 290-296. DOI: 10.1016/j.biombioe.2015.10.008

- Bark content of two shrub willow cultivars grown at two sites and relationships with centroid bark content and stem diameter. Eich, S., T.A. Volk, M.H. Eisenbies. 2015. Bioenergy Research. DOI: 10.1007/s12155-015-9617-y

- Changes in feedstock quality in willow chip piles created in winter from a commercial scale harvest. Biomass and Bioenergy. Eisenbies, M.H., T.A. Volk, A. Patel. 2016. DOI: 10.1016/j.biombioe.2016.02.004

- Evaluation of a Single-Pass, Cut and Chip Harvest System on Commercial-Scale, Short-Rotation Shrub Willow Biomass Crops. Eisenbies, M. H., Volk, T. A., Posselius, J., Foster, C., Shi, S., Karapetyan, S.. 2014. BioEnergy Research, 1-13, June 3, 2014. DOI: 10.1007/s12155-014-9482-0.

- Quality and variability of commercial-scale short rotation willow biomass harvested using a single-pass cut-and-chip forage harvester. Eisenbies, M.H., T.A. Volk, J. Posselius, S. Shi, and A. Patel. 2014. BioEnergy Research 14 Oct 2014, 1-14. DOI: 10.1007/s12155-014-9540-7.

- The effect of bio-carbon addition on the electrical conductive, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. Nan, N., D. DeVallance, X. Xie, J. Wang. 2015. Journal of Composite Materials, April 2016. 50(9), 1161-1168. DOI: 10.1177/0021998315589770

- Winter rye as a bioenergy feedstock: impact of crop maturity on composition. Biotechnology for Biofuels. Shao X, K. DiMarco, T. Richard, and L. Lynd. 2015. February 27, 2015. 8:35. DOI: 10.1186/s13068-015-0225-z

- Establishment and growth of switchgrass and other biomass crops on surface mines. Skousen, J., C. Brown, T. Griggs, and S. Byrd. 2014. Journal American Society of Mining and Reclamation. 3(1): 136-156. DOI: 10.21000/JASMR14010136

- Recently Bred Willow (Salix spp.) Biomass Crops Show Stable Yield Trends Over Three Rotations at Two Sites. Sleight, N. and T. Volk. 2016. Bioenergy Research. DOI 10.1007/s12155-016-9726-2

- Enhanced enzymatic saccharification of shrub willow using sulfolane pretreatment. Wang, K., X. Xie, J. Jiang, J. Wang. 2016. Cellulose. DOI: 10.1007/s10570-016-0875-4

- Microwave assisted hydrolysis of holocellulose catalyzed with sulfonated char derived from lignin-rich residue. Wang, K., X. Xie, Z. Si, J. Jiang, J. Wang. 2014. Advances in Materials Science and Engineering. Vol. 2015, Article ID 106137. DOI: 10.1155/2015/106137

- Integrated Acidogenic Digestion and Carboxylic Acid Separation by Nanofiltration Membranes for the Lignocellulosic Carboxylate Platform. Xiong, B., T.L. Richard and M. Kumar. Journal of Membrane Science. Vol. 489, 1 September 2015. 275-283. DOI: 10.1016/j.memsci.2015.04.022

- Directional liquefaction coupling fractionation of lignocellulosic biomass for platform chemicals. Xu, J., X. Xie, J. Wang, J. Jiang. 2016. Green Chemistry. DOI: 10.1039/c5gc03070f

Fact Sheet

- Introduction to Processing Feedstocks into Biofuels – Ciolkosz

- EcoWillow 2.0: An Updated Tool for Financial Analysis of Willow Biomass -Heavey and Volk

- Maximizing Planted Area and Biomass Production in Shrub Willow Bioenergy Fields -Heavey and Knipfing

- Site Preparation for Willow Bioenergy Crops– Justin P. Heavey and Timothy A. Volk.

- Site Selection for Willow Bioenergy Crops– Justin P. Heavey and Timothy A. Volk.

Research Summaries

- Planting and Maintenance of Willow Bioenergy Crops– Justin P. Heavey and Timothy A. Volk.

- Development of a Single-Pass Cut-and-Chip Harvesting System for Short Rotation Woody Crops – Eisenbies, et.al.

- Exploring On-Farm Pyrolysis Processing of Biofuels– Boateng

- Characteristics of Willow Biomass Chips Produced Using a Single-Pass Cut-and-Chip Harvester – Eisenbies et.al.

- Biomass Crop Production May Benefit from a Wide Spectrum of Marketing Opportunities – Ruamsook and Thomchick

Case Studies

- Ernst Conservation Seeds Transforms Previously Unused Leftover Biomass into Energy Product

- ReEnergy Holdings: Offering Markets for Biomass in the Northeast

- Renmatix Turns Biomass into Sugars for Industrial Use

- Terra Green Energy: Pioneers in Torrefaction for Commercial Co-Combustion

Webinars

Instructional Video

- Commercial Willow Biomass Crops in New York State

Curriculum

- Manufacturing Wood and Grass Pellets – Ciolkosz

Authors

- John Vance, Graduate Student, West Virginia University

- Jingxin Wang, West Virginia University

- Timothy Volk, SUNY-ESF

- Damon Harley, DOE INL

- Susan J. Harlow, Freelance Journalist

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by the Agriculture and Food Research Initiative. This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 2012-68005-19703.

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by the Agriculture and Food Research Initiative. This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 2012-68005-19703.

Led by Penn State University, NEWBio includes partners from Cornell University, SUNY College of Environmental Science and Forestry, West Virginia University, Delaware State University, Ohio State University, Rutgers University,  USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.

USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.