Biomass is transformed into solid & liquid fuels, gas, electricity and heat using a variety of processing methods and equipment.

TOPICS

- Physical Processing

- Thermochemical Conversion

- Biochemical Conversion

- Chemical Conversion

- Combustion and Thermodynamic Conversion

- Looking Forward

- Contributors to This Article

Introduction

One of the main barriers to a successful biomass energy industry is the simple fact that most raw biomass is not immediately useful as an energy source. For example: Corn cannot be poured directly into a fuel tank. Dairy manure cannot be piped into a cookstove. Switchgrass cannot be easily fed into a woodstove. Biofuel crops must be processed in one way or another before they can be a valuable source of energy.

Fortunately, the variety of processing methods and equipment is remarkable, allowing us to transform biomass into useful solid fuels, liquid fuels, gases, electricity, heat or mechanical work. Not all of the processing methods are suitable for on-farm use. Some are very complex, some are very expensive, and others are still in the experimental stage of development. However, many processing methods do have the potential to be used successfully on the farm, or at a small (perhaps cooperative) scale.

The different categories of processing methods are listed below – click on the link to learn more about the topic. The names may seem a bit complicated, but it’s often quite straightforward.

Physical Processing

Chopping, grinding, and compacting of biomass are important steps in creating firewood, wood pellets, briquettes, and cellulosic ethanol.

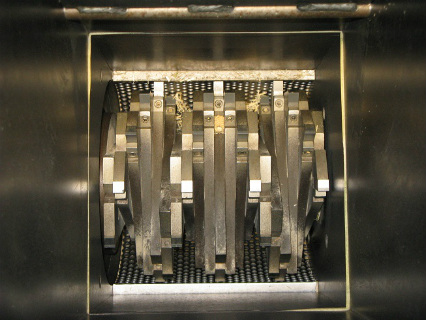

Making it Smaller:

Chippers slice and break biomass into smaller chunks, usually on the order of 70mm (max dimension). The two most common styles are called “drum chippers” and “disk chippers” — named after the shape of the cutting head in the machine. Grinders then slice or pulverize wood or grass into fine pieces, whose maximum size will depend on the design of the machine. Why would you do this? Well, the main reasons for “size reduction” are to 1) make the biomass easier to handle or transport, or 2) increase the reactivity of the biomass (more readily convertible into liquid fuel, heat, or other products).

Making it Bigger (The Densification Process):

Pelletizers and briquetters use heat and pressure to squeeze grounds of biomass together into larger chunks. Oddly enough, we often grind biomass into fine particles just to press it back together into pellets or briquettes. Why do we do this? In the case of pellets (which are typically ~6mm in diameter), it turns out that pellets are very easy to handle — they flow well, and are easily adaptable to things like storage silos and flex augers. Also, the uniform, repeatable size and moisture content of pellets make it easy to design combustion devices that are optimized for high efficiency and low emissions. To learn more about pelletizing, visit one of the following links:

- Manufacturing Fuel Pellets from Biomass – Penn State Publication UC203

- Manufacturing Wood and Grass Pellets Curriculum – fact sheet, presentations, case study, decision tool

Thermochemical Conversion

Have you ever wanted to make your own charcoal? Would you like to run your pickup truck on wood? Thermochemical conversion is the method by which you can turn most any biomass material into solid, liquid, or gaseous fuel, using heat and/or pressure. When biomass is heated up, its molecules break down and rearrange into new configurations. Depending on the conditions under which it is processed, you can end up with any of a variety of fascinating results.

- Torrefaction uses lower temperatures to modify biomass at the molecular level and make it more suitable as a bioenergy feedstock.

- Carbonization converts biomass into charcoal, which in turn is used primarily as a cooking fuel.

- Fast pyrolysis converts biomass into a thick, tarry substance sometimes called “biocrude” or “bio-oil,” a syngas, and biochar. Bio-oil is sometimes “fractionated” into families of compounds/molecules. Further upgrading of the biocrude/fractions is needed to produce final fuels, chemicals and materials.

- Gasification converts biomass into combustible gas that can then be converted into heat, power, or a variety of substances.

To learn more about these interesting topics, visit one of the following:

- Technological Processes: Thermochemical

- Thermochemical Conversion of Biomass to Drop-In Biofuels (webinar archive)

- Thermochemical Conversion of Biomass to Fuels and Chemicals – Pyrolysis and Gasification (webinar archive)

- Biomass Torrefaction: Technology Status and Commercialization, Applications and Challenges for Torrefied Biomass and its Role in Logistics and Trade (international perspective – webinar archive from IEA Bioenergy)

Biochemical Conversion

Most of us know that microscopic organisms are really handy for making tasty treats like bread and yogurt, but did you know that you can also use microscopic organisms to create a variety of useful fuels, including ethanol and biogas? Check out these pages to learn more about this process:

- Technological Processes: Bio-chemical

- Introduction to Biogas and Anaerobic Digestion

- Ethanol from Biomass

- Corn Ethanol Production

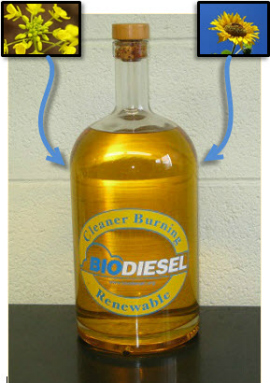

Chemical Conversion

Biodiesel production is probably the most common chemical process that is used, and has been a popular method for producing renewable diesel fuel for generations. While the process of making biodiesel is quite straightforward (if you are careful and follow necessary safety precautions), making high quality biodiesel that performs well in your engine can be quite a challenge, and requires care and attention to detail. Learn more about biodiesel at:

- Biodiesel Resources – from feedstock production and conversion processes, to safety and biodiesel quality.

- Biodiesel Online Library of Resources

Combustion and Thermodynamic Conversion

Perhaps the oldest use of biomass energy is its combustion for heat. In fact, you might argue that fossil fuels are really just old (very old) biomass. But we’ll set that argument aside for now to talk about using wood and grasses as a combustion fuel to provide heat and/or power. Most of us are familiar with fireplaces and wood stoves that have been in use for generations. However, modern combustion systems are much advanced and are different than those of even a few years ago. Developments in design allow us to use fuel more efficiently and produce fewer air emissions, providing clean and renewable heat to homes, farms, offices, schools, hospitals, businesses,and institutions.

Looking Forward

Research and development programs at universities, Department of Energy Labs, USDA, and many companies are continuing to make new discoveries and optimize the processes described above. Regardless of the process, renewable energy, chemicals and materials will require biomass feedstocks, and farmers and agricultural enterprises to produce those feedstocks.

Contributors to This Article

Authors

- Daniel Ciolkosz, Ag Engineering Research Associate, Penn State

Peer Reviewers

- Chris Callahan, Agricultural Engineer, UVM Extension

-

Jill Euken, Deputy Director, Bioeconomy Institute at Iowa State University

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by Agriculture and Food Research Initiative Competitive Grant no. 2012-68005-19703 from the USDA National Institute of Food and Agriculture.

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by Agriculture and Food Research Initiative Competitive Grant no. 2012-68005-19703 from the USDA National Institute of Food and Agriculture.

Led by Penn State University, NEWBio includes partners from Cornell University, SUNY College of Environmental Science and Forestry, West Virginia University, Delaware State University, Ohio State University, Rutgers University,  USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.

USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.