|

|

| Photo: Gary E. Wyatt. |

Introduction

The speed at which tractor engines are operated, travel speed in the field, and the load tractors pull all have a major influence on the fuel efficiency of the equipment. Running equipment at optimal speeds and loads can save significantly on fuel costs.

Optimizing Travel Speed

Field travel speed is a major factor in matching tractor to implement. For many operations, the most desirable travel speed is from 5 to 7 miles per hour (6.4 to 9.7 kph) because most implements are designed to perform high-quality work at these speeds.

Travel speeds below 4 mph (6.4 kph) result in low field capacities, poor soil mixing for tillage operations, and reduced life of the drive train except for certain operations, such as planting, where precise control is required. Operating equipment at high speeds generally increases implement maintenance, increases tire wear, and reduces the life of the implement. It can also break down soil aggregates, which leads to compaction. Field speeds may be limited by heavy yield, rough ground, operator skill, or downed crops. Irregular and small fields, overlap, and large machinery can affect field efficiency.

Optimizing Fuel Efficiency

Most tractor engines have the highest fuel efficiency when operated at or near their rated speed and load (maximum power). Primary tillage implements properly matched to the tractor achieve the best fuel efficiency in the field by pulling loads at the fastest speed possible within the acceptable speed range for the implement. This will also reduce the time requirements for field operations and shock loads on the drive train.

If tractor and implement are improperly matched with resulting partial engine loads, increasing travel speed by gearing up and maintaining a full throttle setting to achieve near maximum engine power will usually increase the fuel required. The additional power required for this increased speed and draft more than offsets the fuel efficiencies gained by running the engine at maximum power. While this common practice does not save fuel, it will reduce time requirements. This time savings may be more valuable than the additional fuel required if more timely operations result in reduced crop losses.

|

Photo: Alexander Morse Photography. |

Fuel versus Time Considerations

Ideally, field operations should require the least possible fuel and time. However, many operations do not require full tractor engine power, even at the fastest travel speed acceptable for high-quality work. In fact, studies indicate that tractor loading in the field averages only about 55% of maximum power. For some of these light loads, combining operations decreases time requirements and increases fuel use efficiency by utilizing more of the tractor’s power. For other light load conditions, shifting to a higher gear and slowing the engine speed to maintain the desired field travel speed can result in 15 to 30% fuel savings.

Normally, operations that require engine loads of 65% or less of a tractor’s maximum power can be performed by gearing up and throttling down. Check the operator’s manual for specific recommendations. However, it is generally safe to reduce engine speed by 20 to 30% of the rated RPM.

Remember not to overload the engine, which will cause engine wear, overheating, and excessive black smoke. To check for overloading, work for a short time at the desired field speed while geared up and throttled down. Then rapidly open the throttle. If the engine easily regains speed, it is not overloaded. If the engine is overloaded, gear down and increase the engine speed to achieve the desired field speed.

If you need a new tractor, consider getting one with a constantly variable transmission. This type of transmission adjusts the gear ratios and engine speed to optimize the tractor’s performance based on the type of load.

Optimal Tractor Speed: An Example

Tractor drawbar power is a combination of field speed and implement draft. This is calculated using this formula:

Drawbar Hp = (lb of Implement Draft x mph Field Speed) / 375

Assume a 100-hp tractor can pull a 20-foot-wide implement at 3 mph. The formula indicates that the same power could be used to pull a 10-foot-wide version of the same implement at 6 mph. Which match is the best? In most situations, the higher field speed and narrower implement is the better choice. The advantages of increasing field speed while maintaining a desired power input by decreasing the implement width include:

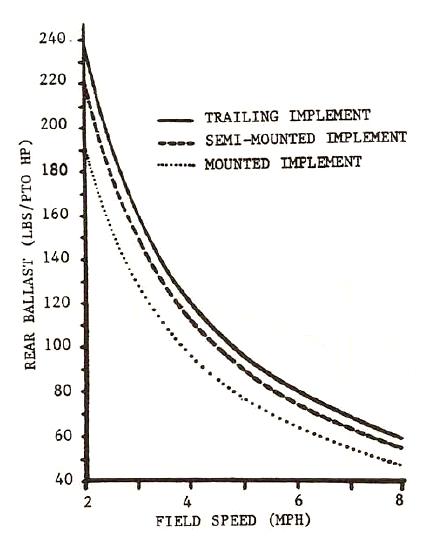

- The narrower implement allows faster field speeds and requires less draft which in turn requires less tractor ballast. The relationship of field speed to rear ballast is shown in Figure 1 below.

- Less tractor ballast means that less tractor power is “wasted” just to move the tractor through the field; see Figure 2.

- A lighter tractor has less potential of soil compaction and less demand for duals.

- Lower implement draft means less torque in the drive train and increased life of the drive train. Figure 3 shows the relationship of a tractor’s drive train life to the travel speed.

|

|

|

| Figure 1. Approximate relationship of rear tractor ballast and field speed assuming operation at 80 percent maximum power and optimum slip, for two wheel drive tractors. | Figure 2. Drawbar power loss from drive wheel slip and tractor rolling resistance as rear wheel ballast changes. Note the “optimum” slip occurs when total loss is minimized. | Figure 3. Estimated relationship of final drive train life with field speed. This assumes that the tractor is appropriately ballasted and operating near 80 percent maximum power. |

Source: Smith and Grisso, Using Tillage Horsepower More Efficiently: Selecting Speed, Slip and Ballast. Conservation Tillage Proceeding 9:79-81. 1990.

In summary, there is a practical maximum travel speed for a tillage operation, usually in the range from 5 to 7 mph. Above this speed, the operator must consider personal safety, damage to the tractor or implement, and poor tillage performance. Field speeds of at least 6 mph will provide more efficient use of available power. Avoid speeds below 5 mph.

Additional Resources

- Using Tillage Horsepower More Efficiently: Selecting Speed, Slip and Ballast. Smith and Grisso, Conservation Tillage Proceeding 9:79-81. 1990.

- Introduction to Energy-Efficient Tractor and Field Operations

- Tractor and Field Operations Energy Efficiency Checklist and Tips

- Introduction to Farm Equipment Energy Efficiency

- Using Tractor Test Data for Selecting Farm Tractors

- Reducing Tillage to Save Fuel

- Gear Up and Throttle Back to Save Fuel

- Optimize Wheel Slip to Save Fuel

- Ballasting Tractors for Optimal Fuel Efficiency

- Match Implement Size to Tractor to Save Fuel

- Optimizing Field Efficiency to Save Fuel

- Machinery Maintenance for Energy Efficiency

- Machinery Cost Estimates. Minnesota Cooperative Extension. 2010.

- Using Tractor Test Data for Selecting Farm Tractors Virginia Cooperative Extension. 2009.

Contributors to This Article

Authors

- Robert Grisso, Extension Engineer, Virginia Tech

- Zane R. Helsel, Extension Specialist in Agricultural Energy, Rutgers University

- Vern Grubinger, Professor, University of Vermont Extension

Peer Reviewers

- Cole Gustafson, Biofuels Economist, North Dakota State University

- Scott Sanford, Senior Outreach Specialist, University of Wisconsin – Madison