EcoWillow is a financial analysis tool developed by SUNY-ESF that allows users to model the costs and revenues of willow biomass production through every stage of the feedstock life cycle from site preparation through planting, harvesting, and transport to an end user for renewable energy

Table of Contents

- Introduction

- Research Purpose

- Research Activities

- What We Have Learned

- Why This Is Important

- For More Information

- Contributors to This Summary

Introduction

EcoWillow is a financial analysis tool for willow bioenergy crops developed by the Willow Project Research Group at the State University of New York College of Environmental Science (SUNY-ESF). The tool was first released in 2008 and has been widely used since then, with downloads by over 1,000 users in 70 countries around the world. The original model was based on 20 years of research and development of willow biomass crops at SUNY-ESF. A new version of this tool, EcoWillow 2.0, was released in October 2014. This article summarizes the purpose of the EcoWillow tool, recent updates, willow production scenarios modeled using the tool, and the implications for commercial willow crops.

Research Purpose

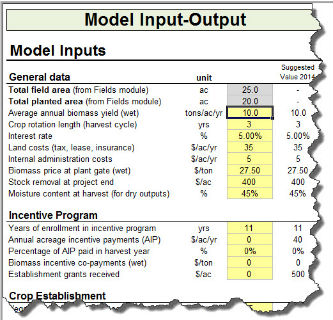

Understanding the factors and conditions that influence returns on investment is critical to the scale-up of shrub willow biomass and the entire bioenergy industry. Producers and investors need to understand the costs, potential returns, and associated time periods in order to make informed decisions about growing perennial energy crops like willow. Willow crops are harvested every three to four years and resprout from the cut stumps after each harvest. The system generally requires multiple harvests to recoup the initial investment in crop establishment, and one planting (Figure 1.) can stay in the ground for 20 years or more. EcoWillow allows users to model the long-term costs and revenues of willow through every stage of the feedstock life cycle from site preparation through planting, maintenance, harvesting (Figure 2. Willow in the Northeast is commonly harvested using a newly developed system developed by SUNY-ESF, New Holland Agriculture, and partners. This system shown here consists of a forage harvester with a specialized woody-crops cutting header that cuts and chips the willow stems in one pass, and then blows the chips into collection vehicles that follow alongside the forage harvester), and transport to an end user (Figure 3.). There are many variables associated with each stage of the life cycle, and inputs into EcoWillow can easily be changed to reflect user-specific conditions and demonstrate the interaction between variables in the system.

Research Activities

EcoWillow 2.0 has been comprehensively updated based on the latest research studies from trials across North America, data collected from commercial willow operations, and feedback from commercial growers. The harvesting module of EcoWillow 2.0 has been updated based on the development and testing of a single-pass cut-and-chip harvesting system under development since 2008 in collaboration with New Holland Agriculture and other partners. A new module in EcoWillow 2.0 allows users to include multiple fields/locations with different transport distances in one project analysis, and enables more precise calculations of headlands and planted areas. EcoWillow 2.0 also includes a more user-friendly design and other improvements based on feedback from various stakeholders in the willow industry. Four crop-production scenarios have been developed using EcoWillow 2.0: a base case scenario with conservative assumptions of profitability; an improved scenario that adds best-practice targets to the base case; an incentivized scenario that adds possible incentives to the base case; and an improved-incentivized scenario that adds both potential best practices and incentives to the base case. These scenarios demonstrate the impact of key variables on costs and revenues and the potential for willow biomass crops to produce favorable returns on investment.

What We Have Learned

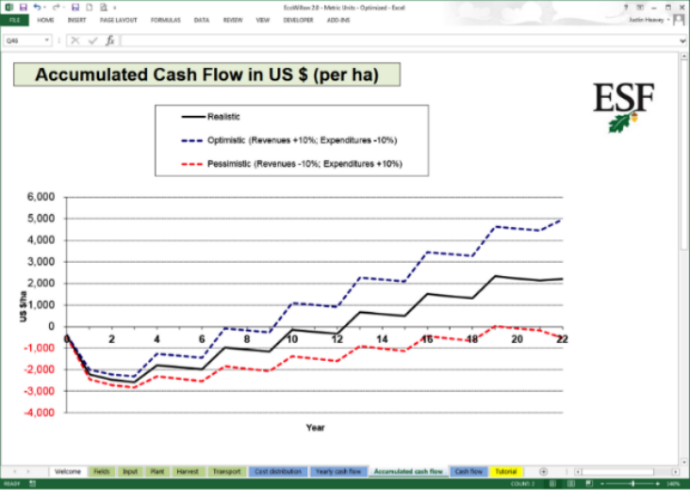

Expected returns on investment are low in the 2014 base-case scenario for shrub willow production, which represents conservative estimates of profitability that should be easily achievable by most growers in the Northeast. When best-practice targets and expected near-term system improvements (such as higher yields from new willow cultivars) are added to this base-case scenario, the model outputs show more favorable returns on investment with an internal rate of return (IRR) around 5%, and a payback period of 13 years (three harvests). The break-even price in this scenario is about $27 per green ton. Adding possible USDA Biomass Crop Assistance Program (BCAP) payments (or similar incentives) to the base case produces returns on investment that are similar to the best-practice scenario. Expected returns on investment are most favorable when both best practice targets and possible BCAP incentive payments are added to the base case. In this scenario, the payback period can be as short as seven years (two harvests) after planting, with an IRR around 20% and a break-even price around $20 per green ton. Details on each of these hypothetical crop production scenarios and the associated inputs and outputs are available in fact sheets on the Willow Project homepage (www.esf.edu/willow).

Because of the many variables and range of possible inputs across the life cycle of a willow planting, making small changes to just a few variables at each stage of production can substantially reduce costs and increase revenue. It is important to understand how different variables affect profitability and to make improvements wherever possible to generate favorable returns in commercial bioenergy production. Certain variables can have a large impact on profitability and must be carefully considered and managed such as the percentage of land left unplanted for headlands and other areas, the price paid for planting stock (cuttings), the use of fertilizers, biomass yield, transport distance, and the price received per ton of biomass.

Why This Is Important

Profitability is critical to the survival and growth of any business or industry that includes bioenergy crops. EcoWillow is a user-friendly tool that can assist in the financial analysis of producing, harvesting, and transporting willow biomass. Users can customize the example base-case scenario of crop production to their own specific conditions and best-practice targets and easily see how adjusting different variables affects returns, which can inform decisions about investing in willow and the types of management activities needed. EcoWillow will be updated and improved as collaboration between producers, researchers, and industry partners spurs innovation and advances the system. Future analyses by SUNY-ESF will build on the basic crop production scenarios by incorporating uncertainty and data distributions to determine the probabilities of achieving target biomass prices and net present values.

For More Information

The latest versions of the EcoWillow model and supporting documentation can be downloaded for free from the Willow Project website (go to www.esf.edu/willow and follow the links for EcoWillow). Both English and metric unit versions of the model are available, along with several fact sheets, an instructional video, and contact information for follow-up inquiries. This work has been supported by the New York State Energy Research and Development Authority (NYSERDA), the United States Department of Energy (USDOE), and the US Department of Agriculture National Institute of Food and Agriculture (USDA NIFA) through the Northeast Woody/Warm-season Biomass Consortium (NEWBio).

-

NEWBio Project Resources – information on the research, opportunities and challenges in developing a sustainable system for the production of biofuels.

-

Willowpedia: A Willow Energy Crop Information Resource at Cornell University.

Contributors to This Research Summary

Authors

- Justin Heavey, Senior Research Support Specialist, Willow Project Research Group at SUNY ESF, College of Environmental Science and Forestry www.esf.edu/willow

- Timothy Volk, Senior Research Associate, SUNY College of Environmental Science and Forestry

Peer Reviewer

- Michael Jacobson, Professor of Forest Resources, Penn State University, College of Agricultural Resources

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by Agriculture and Food Research Initiative Competitive Grant no. 2012-68005-19703 from the USDA National Institute of Food and Agriculture.

The Northeast Woody/Warm-season Biomass Consortium – NEWBio is supported by Agriculture and Food Research Initiative Competitive Grant no. 2012-68005-19703 from the USDA National Institute of Food and Agriculture.

Led by Penn State University, NEWBio includes partners from Cornell University, SUNY College of Environmental Science and Forestry, West Virginia University, Delaware State University, Ohio State University, Rutgers University,  USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.

USDA’s Eastern Regional Research Center, and DOE’s Oak Ridge National Laboratory and Idaho National Laboratory.